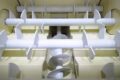

Breaker for reliable processing of your products

Pressure, temperature and humidity cause bulk materials to clump together and partially cake into a monoblock. The lump breaker ensures that the agglomerates are safely broken up: from slight clumping to completely hard-packed units. This ensures your product flow during handling and supply to the production line.

Advantages for your bulk material handling

Robust construction

Many years of experience with a wide variety of products are the basis for this technique.

Standardised and customised versions

1, 2 or multi-shaft versions for the best possible adaptation to your application.

Dust-free breaker

Closed operation for a safe and environmentally friendly overall concept.

Coarse reduction of the products

Guarantee of trouble-free operation of the system.

Breaker for breaking up agglomerates

- Breaking up of agglomerates in the chemical industry, e.g., powders, salts, blocked granulates and similar products

- Polished versions: for fast and hygienic cleaning for food applications

- Quick cleaning due to pull-out device and inflatable seal

- Different sealing systems: stuffing box, shaft sealing, or special sealing systems for food or chemical applications

- Gas-tight design of the breakers, even with the most difficult processes

- Integration of washing nozzles for the safe removal of product residues

- Version for gas or dust hazardous areas (zone 1/2 or 21/22) is possible

- Robust, compact crusher housing in welded construction for integration into existing plants

Finding a solution together

Whether it is components, systems or complete turnkey solutions “as a service”: Let our bulk material experts advise you on your challenges.

Our solution in action

Application areas

Solutions

Emptying

Systems for the dust-free emptying of big bags, containers, drums and octabins.

See solutions

Conveying/Dosing

Conveying systems and dosing systems manufactured for your application.

See solutions