Babycare

Pacifiers, bottle teats, cutlery and toys of all shapes and colours are just a few examples of the endless possibilities where silicone is used for a happy start in life.

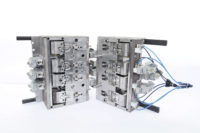

In the field of LSR the mould is the “supreme discipline”. It shapes your product. If the mould is perfect, your product will be perfect. Our know-how and experience in mould design ensure that you get the product you need to succeed in the market.

We are masters of the entire LSR process: a system in which the interaction of the system components – the mould, cold runner, end-of-arm moulding, dosing and mixing system, and the injection moulding machine, is decisive for the product. We will be happy to advise you on the optimization options for your product or for the manufacture of your product.

In the 40 years of EMDE’s corporate history in the LIM sector, we have consistently specialized in the processing of LSR and HTV and transformed our company from a pure mould maker to a fully comprehensive system supplier.

More than 90 % of our expert personnel know the LSR business from the ground up as trained mould mechanics with subsequent further training. They form the basis for more than 600 operating systems on all continents.

Not all silicone is the same, because each product has its own requirements. Through our experience, we know what matters. Whether you need a customized solution or a standard service: We accompany you right from the start in product and process development, support you with our services, and can offer you a complete solution on request.

Our solutions are based on your product specifications and production requirements, including further advice and training opportunities in house or on site. And that across multiple industries. At the end of our work, we guarantee a future-proof, sustainable and economic solution that gives you a competitive advantage in your relevant market.

This is what we mean by partnership.

The EMDE Group also includes the company EMDE Automation, which offers solutions for your bulk material handling.

Are you looking for solutions for your bulk material handling?

The low-viscosity material LSR enables parts with complex geometries and the finest detailing to be injection moulded. The highest precision in mould making and many years of know-how in the process itself are the prerequisites for automated production systems.

Our team of highly motivated and innovative employees is always pursuing new developments, which is why EMDE is known in the market for its flexibility and willingness to experiment.

Standardized mould systems with exchangeable cavities or customized high-performance moulds for processing liquid and solid silicones are our core competence. We design 1K or 2K injection moulds with one or more cavities. Whether your product has extremely thin walls, high optical, haptic or technical requirements, the starting point for building the mould is your product.

Tailored to the mould, the cold runner ensures a reliable, balanced injection moulding of the moulded part.

We supply rheologically balanced and adjustable valve gate systems. In order to inject a higher number of cavities, up to 64 cavities can be filled directly via cold runner systems. The systems are driven pneumatically or mechanically. We can offer individual solutions, depending on the component requirements.

We are represented for you in the following sectors:

Pacifiers, bottle teats, cutlery and toys of all shapes and colours are just a few examples of the endless possibilities where silicone is used for a happy start in life.

The possibilities of LSR and HTV as well as requirements for silicone mould making in the medical sector are practically limitless: almost burr- and particle-free clean room production, sprue-free gating, sealing technology, electronic components overmoulded with LSR, etc. From the smallest components through 2K-LSR multi-component technology to prostheses – we have the solution for you.

We provide support for 1K silicone seals, multi-component parts, 2K silicone injection moulding, lenses made of high-purity and translucent liquid silicones, sensor technology embedded in LSR and much more – the list of possibilities can be continued almost indefinitely.

Baking forms, brushes, food containers, children’s toys, hygiene articles, and many other household items are made of silicone. Attractive colouring and shaping in combination with food and skin compatibility make silicone an indispensable material and bring real added value to our lives.

We love what we do and look for colleagues who share our passion.

With the EMDE Group as your employer, you will not only benefit from the advantages of a firmly established, technologically leading and internationally active company. With us, you will also have the opportunity to get involved in exciting projects and tasks and to fully develop your strengths.